Perma-tec

Perma-tec company founded in 1964 developed leadership in the single-point lubrication system. All perma products are developed, tested and manufactured in the company’s headquarters in Germany.

For more than 50 years, perma has stood for innovative and creative lubrication solutions. Perma single- and multi-point lubrication systems are used in almost all types of industries and applications around the world.

Why Automatic lubrication?

Minimize Risks With Manual Lubrication

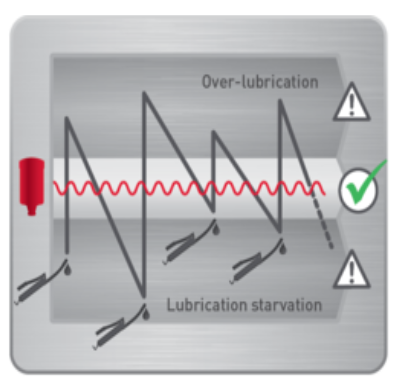

- Over-lubrication (too much lubricant)

- Increase in operating temperature

- Damage to contact seals

- Excessive lubricant consumption

- Lubrication starvation (too little lubricant)

- Increase in friction and wear

- Risk of dry runs

- Automatic lubrication with perma lubrication systems ensures constant supply of the ideal lubricant quantity. Unlike manual lubrication, over-lubrication or lubrication starvation can be prevented.

Advantages of Perma

Causes of failure in roller bearings

- Insufficient lubricant quantity

- Aged lubricant

- Unsuitable lubricants

- Solid contamination

- Well thought-out lubrication strategies have a great influence on extending the service life of greased bearing

- Lubrication with Prema lubrication systems can prevent up to 75% of all bearing failures.

Cost Effectiveness

- Perma reduces costs by up to 25 %

- Perma Automatic lubrication minimizes premature wear and downtimes. Expensive repair and maintenance costs are reduced.

- High equipment availability through automation

- Maintenance intervals can be scheduled during downtimes

- Reduction in repair and maintenance costs

- Management of lubrication points with lubrication systems using free perma MLP Software

Workplace Safety

Perma reduces the risk of accidents by up to 90 %

Using perma lubrication systems increases workplace safety.

Perma lubrication systems minimize contact between human and machine and make an important contribution to workplace safety.

Reduction of time spent in hard-to-access dangerous areas

Lubrication systems prevent direct contact with hazardous lubricants

Reduction of slipping accidents caused by lubricant contamination

Applications

Drive chain lubrication(bolt stock conveyor)

Roller bearing lubrication in a hot-dip galvanising line

Lubrication of a fan drive shaft bearing

LUBGRAF SYNOILS PRIVATE LIMITED

Provides Advanced & most Innovative Lubrication Solutions.

Fifty plus years of experience in the Industry provides an extra edge to find the best possible

solution.

Continuous Improvements & Advance Technology helps the Customer to increase production

and Maximize Efficiency while Lowering Overall Cost.

PRODUCT RANGE OF LUBGRAF

- Grease, Gear Lubricants, Compressor Oils, Aerosols, Anti-Seize Compounds etc

- Water, Powder & Oil Base Lubricants for Cold /Warm and Hot Forging / Extrusion

- Oil & Dispersions for Cold Drawing & other metal forming applications

- Wax, Oil & Water based Rust Preventive & Rust Removers

- Graphite & Non Graphite based lubricants for Die Casting

- Neat & Soluble oils, semi synthetic & synthetic fluids for cutting &machining

- Range of water & solvent base degreasing agents & industrial cleaners